| |

| CLIENTS |

|

A BRIEF EXCERPT OF OUR CLIENT LIST FOR

SAWMILL EQUIPMENT

Allegheny Wood Products

Associated Hardwoods

Battle Lumber

Beasley Forest Products

Bradford Forest Products

Cherry Forest Products

Domtar Inc.

Emporium

Gilkey Lumber

Hartzell Hardwoods

Heideman Lavern & Sons

Hermitage Hardwood

Herwynen

Horizon Forest Products

Johnson Brothers

Laidig Systems

Mullican Flooring

Niagara Sawmills

Northland Power

PalletOne

Pinetec Ltd.

Potomac Supply

RAM Forest Products

Sexton Lumber

Spruce Forest Products

Tembec

Ward Lumber

Weaber Lumber

Wolf Systems

|

|

|

|

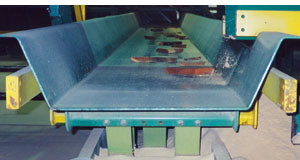

| TS VIBRATING CONVEYORS |

|

|

|

With a wide range of styles, sizes and options to choose from, TS Manufacturing has a vibrating conveyor solution to suit your needs. Depending upon application requirements, we can supply Heavy Duty Coil Spring Vibrating Conveyors, Medium or Light Duty Leaf Spring Vibrating Conveyors, complete with Screen Out Sections and Transition Spouts. For more specialized applications, our Counter Balanced Vibrating Conveyors and Vibrating Floor Systems both available in Light, Medium and Heavy Duty configurations.

|

|

|

POSITIVE ACTION

ECCENTRIC DRIVE SYSTEM

Every TS Manufacturing Vibrating Conveyor utilizes our Positive Action Eccentric Drive, that is ruggedly built to sustain normal load variations that occur during operation. The drive incorporates a special shock absorbing wrist pin, that substantially prolongs the life of the drive train. |

| |

|

|

|

| |

|

|

|

|

NATURAL FREQUENCY

Using state of the art engineering facilities, every conveyor is designed to operate as close as possible to Natural Frequency, to minimize operating power requirements and part stress while under load. |

| |

|

|

|

| |

|

|

|

|

EXTREMELY LOW MAINTENANCE

Every Leaf Spring Series Vibrating Conveyor utilizes a special material for the springs that is impervious to moisture, oils and most chemicals - allowing for longer spring life. Combine this with our specialized wrist pin and our ability to custom design for your specific needs, and TS consistently provides products with a low cost of ownership. |

| |

|

|

|

| |

|

|

|

|

OPTIONS

Built in screen out sections to reduce maintenance on components down the line

Fiberglass sections for use with metal detectors

Magnetic trap to catch metal particulate

Transitions designed to suit your application

Custom profiles and shapes are available |

| |

|

|

| |

|

|

|

|